The Complete Guide to Lug Nuts and Bolts: Fitment, Types, and Measurements

Lug nuts and bolts are small but critical components in vehicle safety. They secure the wheel to the hub, ensure proper alignment, and handle immense loads during braking, acceleration, and cornering. Choosing the right lug hardware and installing it correctly prevents wheel-off accidents, vibration, and premature wear of wheels, studs, and hubs.

This article covers everything you need to know: fitment, types, seat designs, conicity, measurements, and best practices according to TIA-certified guidelines.

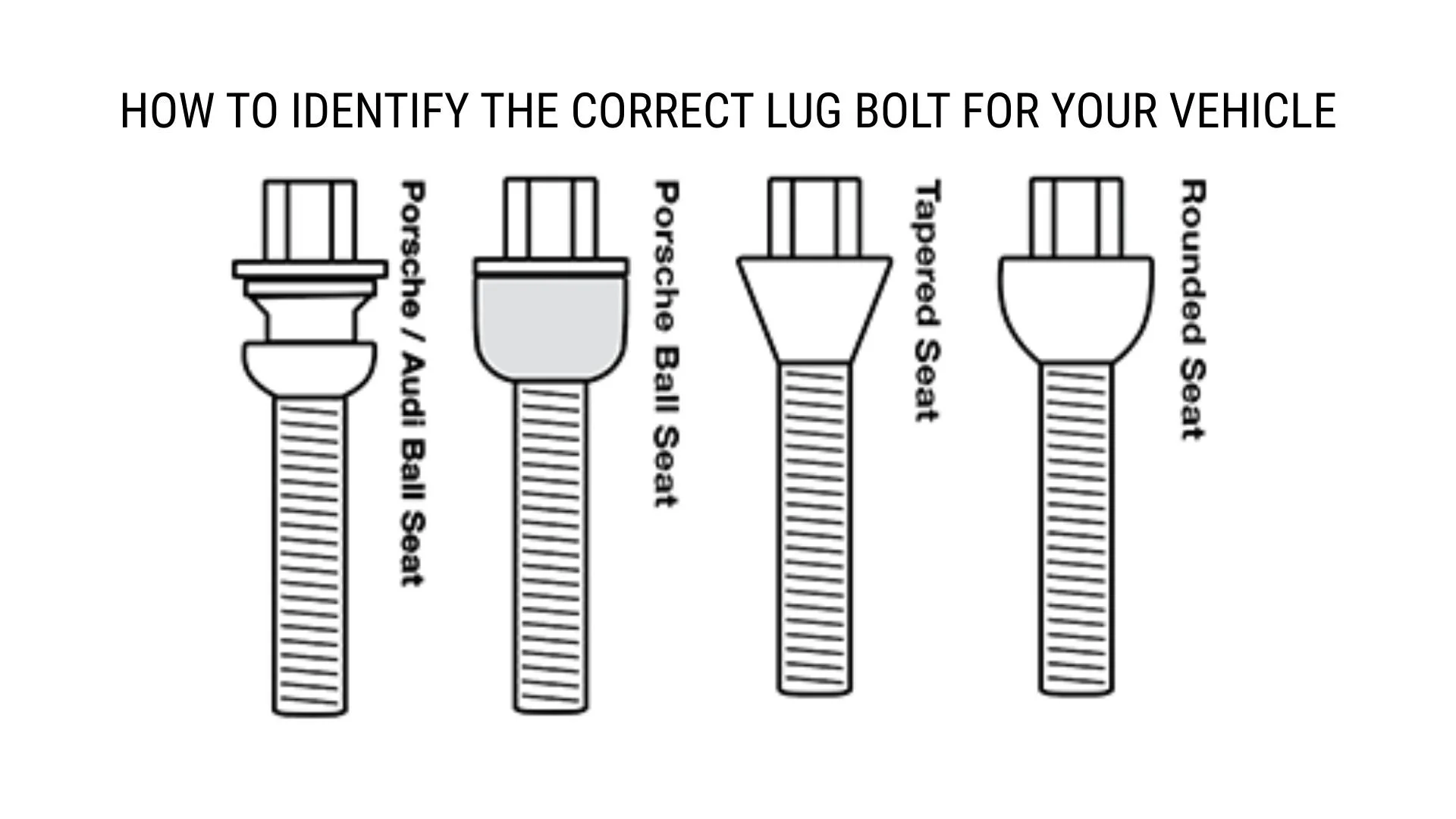

1. Lug Nuts vs. Lug Bolts

Lug Nuts: Thread onto wheel studs that protrude from the hub. Common in North American and Japanese vehicles.

Lug Bolts: Thread directly into the hub, with no protruding studs. Common in many European vehicles (BMW, Mercedes, Audi, VW).

Key difference: A lug nut needs a stud; a lug bolt serves as both stud and nut in one.

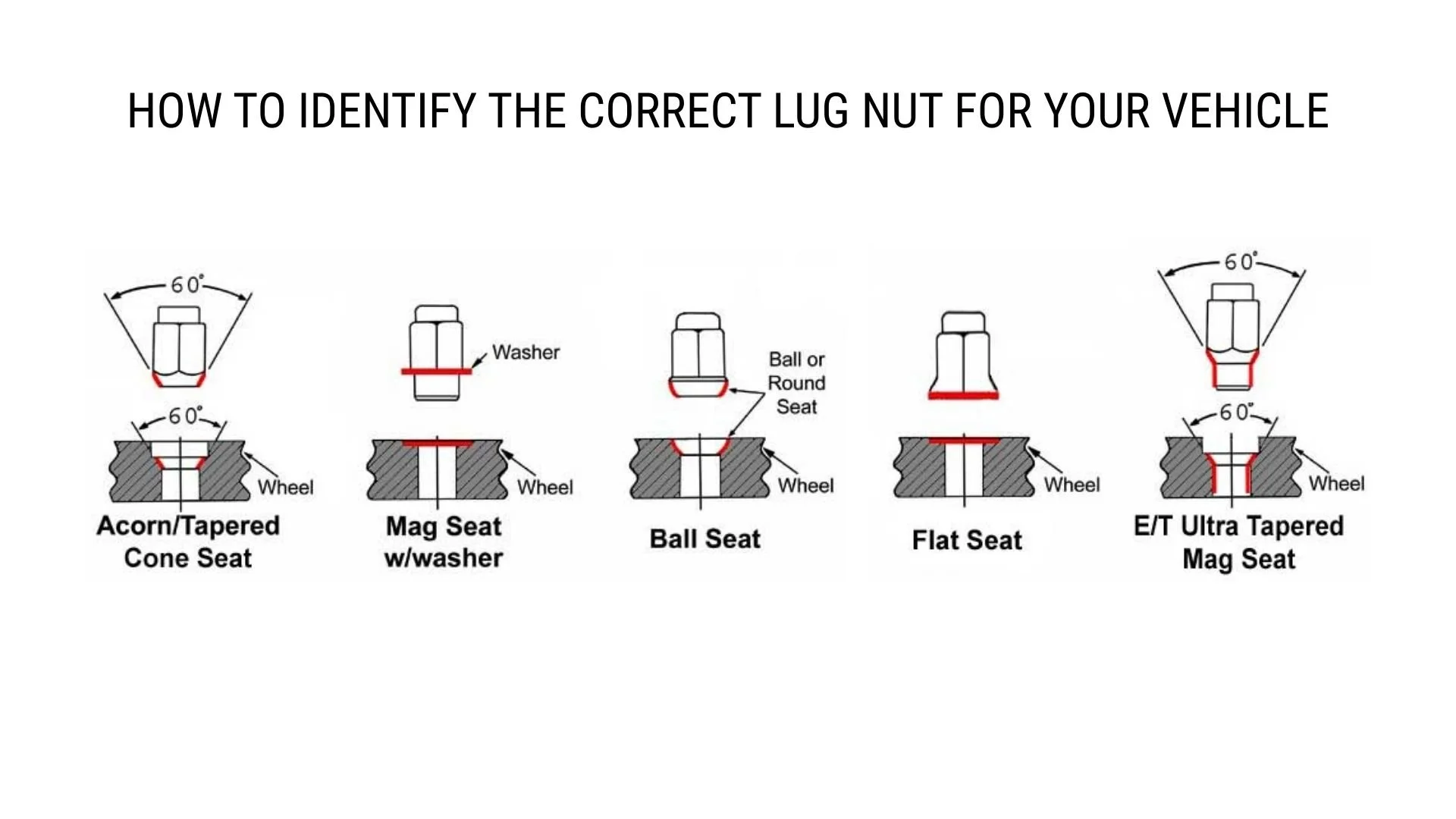

Lug nut identification diagram

2. Common Lug Nut Types

Conical (Tapered Seat)

Most common type.

60° taper matches wheel seat.

Provides centering and secure clamping.

Ball (Radius Seat)

Rounded seat matches ball radius in wheel.

Common on German vehicles.

Flat Seat

Requires washer.

Common on some aftermarket wheels and Toyota OE wheels.

Mag Style (Shank Style)

Extended shank fits into wheel hole.

Uses washer to clamp.

Spline Drive

Slim profile for aftermarket wheels with small lug holes.

Requires a special keyed socket.

Tuner Style

Compact nuts with unique drive patterns for security.

Lug bolt identification diagram.

3. Lug Bolt and Nut Measurements

Thread Size

Defined by diameter × pitch × length.

Example: M12 × 1.5 × 28 mm means:

Diameter: 12 mm

Thread pitch: 1.5 mm per thread

Length: 28 mm

Common sizes:

M12 × 1.25, M12 × 1.5, M14 × 1.25, M14 × 1.5

Some trucks use 7/16", 1/2", 9/16", 5/8" UNF.

| Thread Size | Common Use | Notes |

|---|---|---|

| M12 × 1.25 | Nissan, Subaru | Finer pitch, more turns |

| M12 × 1.5 | Toyota, Honda, GM, Ford | Most common |

| M14 × 1.25 | BMW, Mercedes | Often ball seat |

| M14 × 1.5 | Audi, VW, Dodge Ram | SUVs & trucks |

| 7/16"-20 | Older Ford/GM | UNF thread |

| 1/2"-20 | Light trucks, Jeep | Very common |

| 9/16"-18 | Heavy trucks | High load |

| 5/8"-18 | Commercial trucks | High torque |

Seat Conicity (Angle)

Most conical nuts: 60° taper

Ball seat radius: e.g., R12, R14

Must match wheel seat exactly — mismatched seats cause vibration and wheel damage.

Shank Diameter and Length (Mag Style)

Must precisely match wheel’s lug holes for proper seating.

| Seat Type | Angle/Radius | Common Applications |

|---|---|---|

| Conical (Tapered) | 60° | Most OEM + aftermarket wheels |

| Ball (Radius) | R12 / R13 / R14 | German vehicles (VW, BMW, Mercedes) |

| Flat | Flat with washer | Toyota OE, some aftermarket alloy wheels |

| Mag / Shank | Straight shank + washer | Custom wheels, some Toyota/Lexus |

| Spline Drive | Slim-profile seat | Aftermarket tuner wheels; keyed socket |

4. Torque Specifications

Over-tightening can stretch studs and damage threads.

Under-tightening risks wheel-off incidents.

Always use a calibrated torque wrench and follow vehicle manufacturer’s torque specs.

Typical ranges:

Passenger cars: 80–100 ft-lb (108–135 Nm)

SUVs/light trucks: 100–140 ft-lb (135–190 Nm)

Heavy trucks: 450–500 ft-lb (610–680 Nm)

Best Practice (TIA R.I.S.T.):

Remove

Inspect

Snug

Torque

| Vehicle Class | Torque Spec (ft-lb) | Torque Spec (Nm) |

|---|---|---|

| Passenger cars | 80–100 | 108–135 |

| CUVs & small SUVs | 90–110 | 122–149 |

| Full-size SUVs & light trucks | 100–140 | 135–190 |

| Heavy-duty trucks (reference only) | 450–500 | 610–680 |

5. Hub-Centric vs. Lug-Centric Wheels

Hub-Centric: Wheel centers on hub bore. Lug nuts provide clamping force only. Most OEM wheels.

Lug-Centric: Wheel centers on lug nuts. Requires perfectly matching seat type. Common in aftermarket wheels.

6. Extended and Locking Lug Nuts

Extended thread: For wheels with thick mounting pads.

Locking lug nuts: Anti-theft design; requires a unique key.

7. Material and Finish

Steel (chrome-plated): Most common. Durable, affordable.

Aluminum: Lightweight but weaker; not for heavy-duty use.

Black oxide / colored coatings: Cosmetic aftermarket finishes.

8. Inspection and Replacement

Check threads: Replace if stripped, cross-threaded, or corroded.

Seat wear: Replace if taper/ball surface is deformed.

Length fitment: At least 6.5 full turns of engagement for passenger vehicles (≈ 1 × bolt diameter). Trucks require more.

9. Safety Notes for Tire Technicians

Never use impact gun for final torque — always finish with a torque wrench.

Retorque after 80–100 km (50–60 miles).

Replace broken, stretched, or seized studs immediately.

Always use nickel-plated or valve-compatible cores for TPMS-equipped wheels.

Conclusion

Lug nuts and bolts are precision parts that must match the wheel and hub exactly in size, seat type, and torque specification. At Sparky X Mobile Tire Shop, we use TIA-certified practices to ensure every wheel is secured correctly, with safety as the top priority.